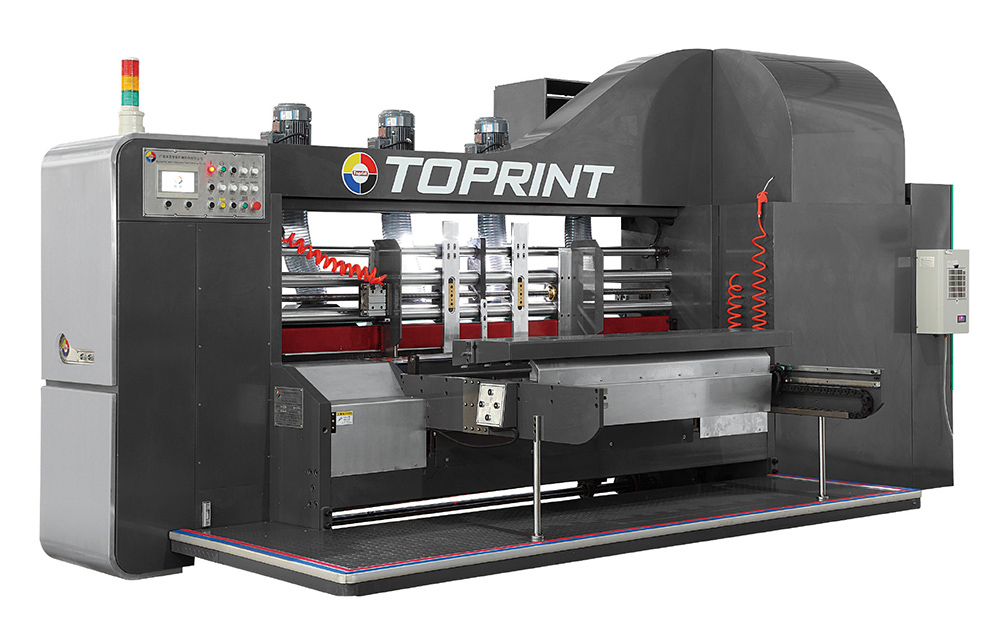

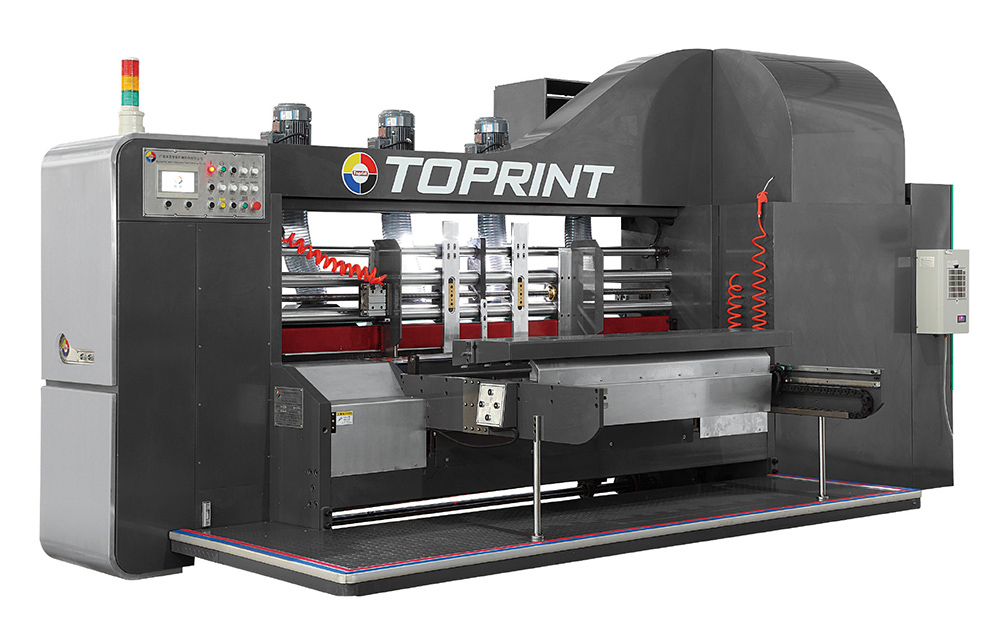

Fully Computerized High Speed Flexo Printer Slotter Die-cutter

Features

-

Adopts independent Central Computer (with Keyboard & Mouse) match with PLC and Touch Screen in each Unit for automatic operation, all operation function can achieve automatic adjustment by data input or Order Management system, Easy to Operate, Fast Order Change, and can connect with Corrugated Paperboard Production Line Management System (Short for CPMS).

-

All the Electronic Components are adopts International First Brand, Stable and Durable, the Main Control Box equipped with Industrial Constant Air Conditioner, Each Unit equipped with Anti-dust, Air Fan to ensure reliable and durable working performance.

-

The whole machine equipped with Oil Balance and Automatic Circle Lubrication System.

-

All the Main Transmission Gears adopt special imported material, carburizing and quenching, precision grinding, long life time and durable.

-

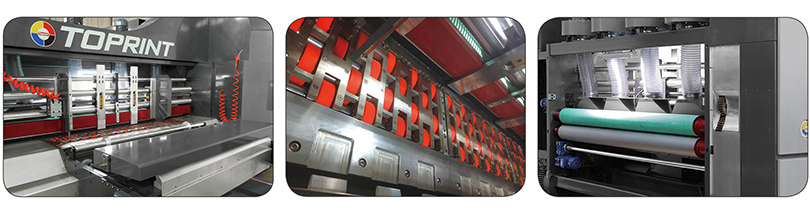

Vacuum Transfer, widely applicable for different cardboard, the suction box will be combined together to ensure same pressure when machine is closed, which makes more accurate printing, and save adjusting time and cardboard.

-

Internal video surveillance production, can check the cardboard transmit in any moment.

-

Can easy match with Pre-feeder, which can increase the level of automation and decrease the labor intensity.

Technical Parameter

|

Technical Date

|

Unit

|

0920

|

1224

|

1628

|

|

Top Speed

|

sheets/min

|

300

|

250

|

180

|

|

Economic Speed

|

sheets/min

|

150-250

|

120-220

|

100-180

|

|

Max. Sheet Size

|

mm

|

900x2000

|

1200x2400

|

1600x2800

|

|

Min. Sheet Size

|

mm

|

280x700

|

350x720

|

450x850

|

|

Skip Feed Size

|

mm

|

1200x2000

|

1400x2400

|

1800x2800

|

|

Max. Printing Area

|

mm

|

890x1960

|

1190x2360

|

1600x2760

|

|

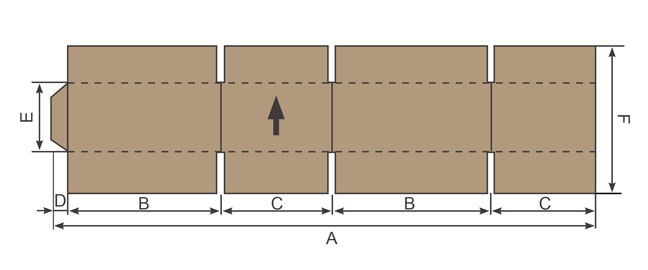

Slotting Space Normal Knife Min.Size (BxCxBxC)

|

mm

|

150x150x150x150

|

160x160x160x160

|

160x160x160x160

|

|

Slotting Space Reverse Knife Min.Size (BxCxBxC)

|

mm

|

260x50x260x50

|

270x60x270x60

|

320x120x320x120

|

|

Max. Slot Depth Size

|

mm

|

250

|

320

|

450

|

|

Min. Box Height Size (E)

|

mm

|

110

|

110

|

160

|

|

Max. Die-Cutting Size (FxA)

|

mm

|

850x1950

|

1150x2350

|

1530x2750

|

|

Sheet Thickness

|

mm

|

1.5-11

|

1.5-11

|

1.5-11

|

|

Thickness Of Printing Plate

|

mm

|

7.2

|

7.2

|

7.2

|

Feeding Unit - Lead Edge Feeder

-

Standard Machine with Mechanical Lead Edge Feeder and Servo Control Non-crash Wheel Feeder is Optional.

-

Air Suction plus Multi-brushes and Anti-static for dust remove, and air channel for central collection of dust.

-

Continuous Feed or Skip Feed is available.

-

Main Motor is equipped with self-protection device.

-

Permanent magnet fan frequency conversion control vacuum air flow and pressure, can adapt for different cardboard.

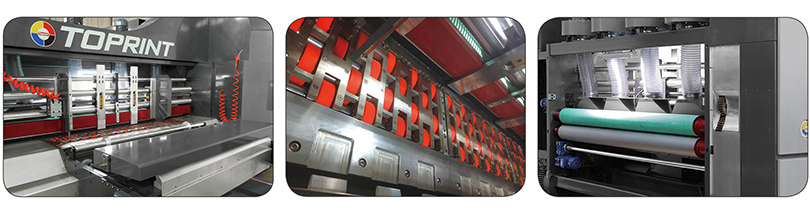

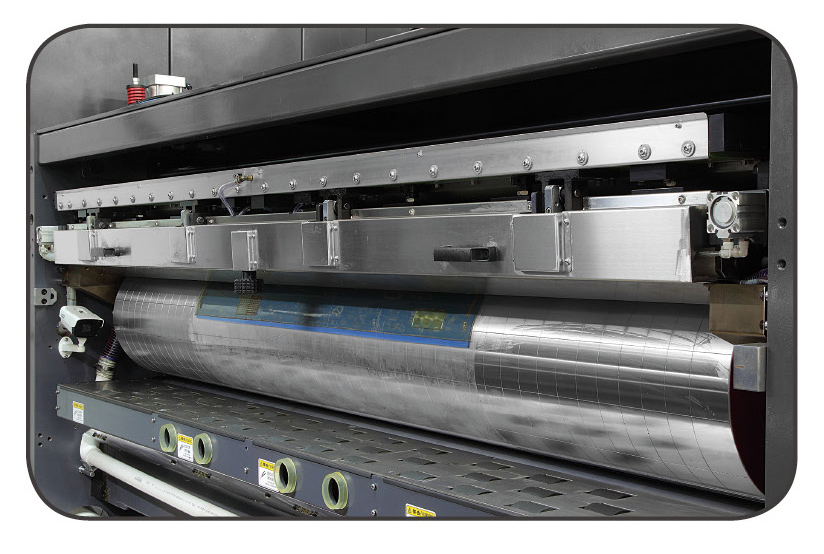

Printing Unit – Top Printing / Vacuum Transfer

-

Vacuum Transfer, can adjust Air Volume automatically according size of cardboard.

-

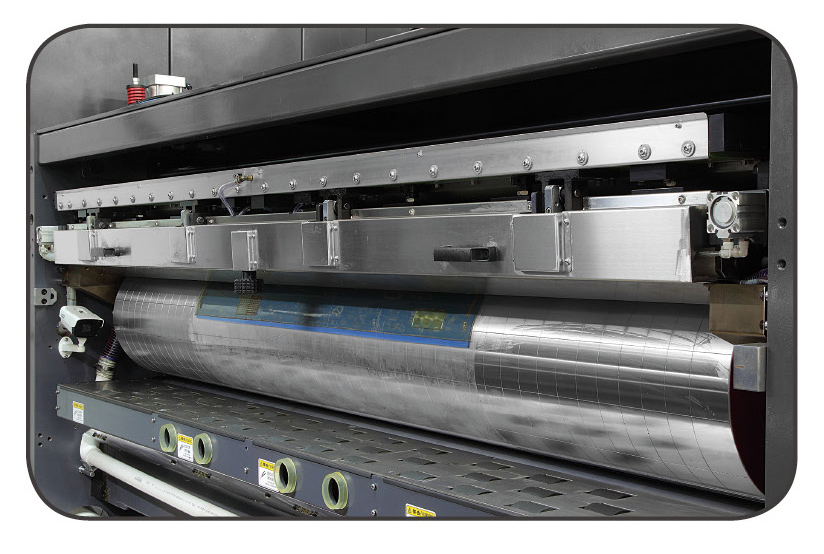

Standard machine equipped with Rubber Roller, Chambered Doctor Blade is Optional.

-

Chambered Doctor Blade is equipped with Fast Ink-return and Automatic Cleaning Device.

-

Standard machine equipped with Normal Ceramic Roller, NOVA, ART Ceramic Roller for Optional.

-

Reel Hanging Plate, Ratchet Locking Device to make sure hanging plate alignment is more accurate.

-

Printing Register is Servo Control.

-

Small IR Device is optional.

-

The suction box will be combined together to ensure same pressure when machine is closed, which makes more accurate printing, and save adjusting time and cardboard.

-

Can check the cardboard transmit situation in Central Computer.

Slotting Unit – 8 shafts Transmission

-

8 Shaft Transmissions, Pre-creasing, Big/Small Creasing, Single Shaft Slotting or Pre-creasing, Creasing, Dual Slotting is Optional.

-

Linear Guiding structure combined with Ball Screw for Transverse adjustment to make sure accurate knife fitting, stable movement.

-

Transverse, Box Height, Gaps adopts computerized or motorized adjusted.

-

Slotting Register is Servo Control, more precision.

-

Elastic Corner Cutter Structure to suitable for different thickness cardboard.

Slotting Unit – 8 shafts Transmission

-

8 Shaft Transmissions, Pre-creasing, Big/Small Creasing, Single Shaft Slotting or Pre-creasing, Creasing, Dual Slotting is Optional.

-

Linear Guiding structure combined with Ball Screw for Transverse adjustment to make sure accurate knife fitting, stable movement.

-

Transverse, Box Height, Gaps adopts computerized or motorized adjusted.

-

Slotting Register is Servo Control, more precision.

-

Elastic Corner Cutter Structure to suitable for different thickness cardboard.

Die-cutting Unit – Independent Frequency Motor for Line Speed Compensation

-

Die-cutting Rubber Cylinder is driven by independent frequency motor for line speed compensation. And Servo control is optional.

-

Segmented Rubber Anvil and transverse moving is 30mm.

-

With Automatic Grinding Device.